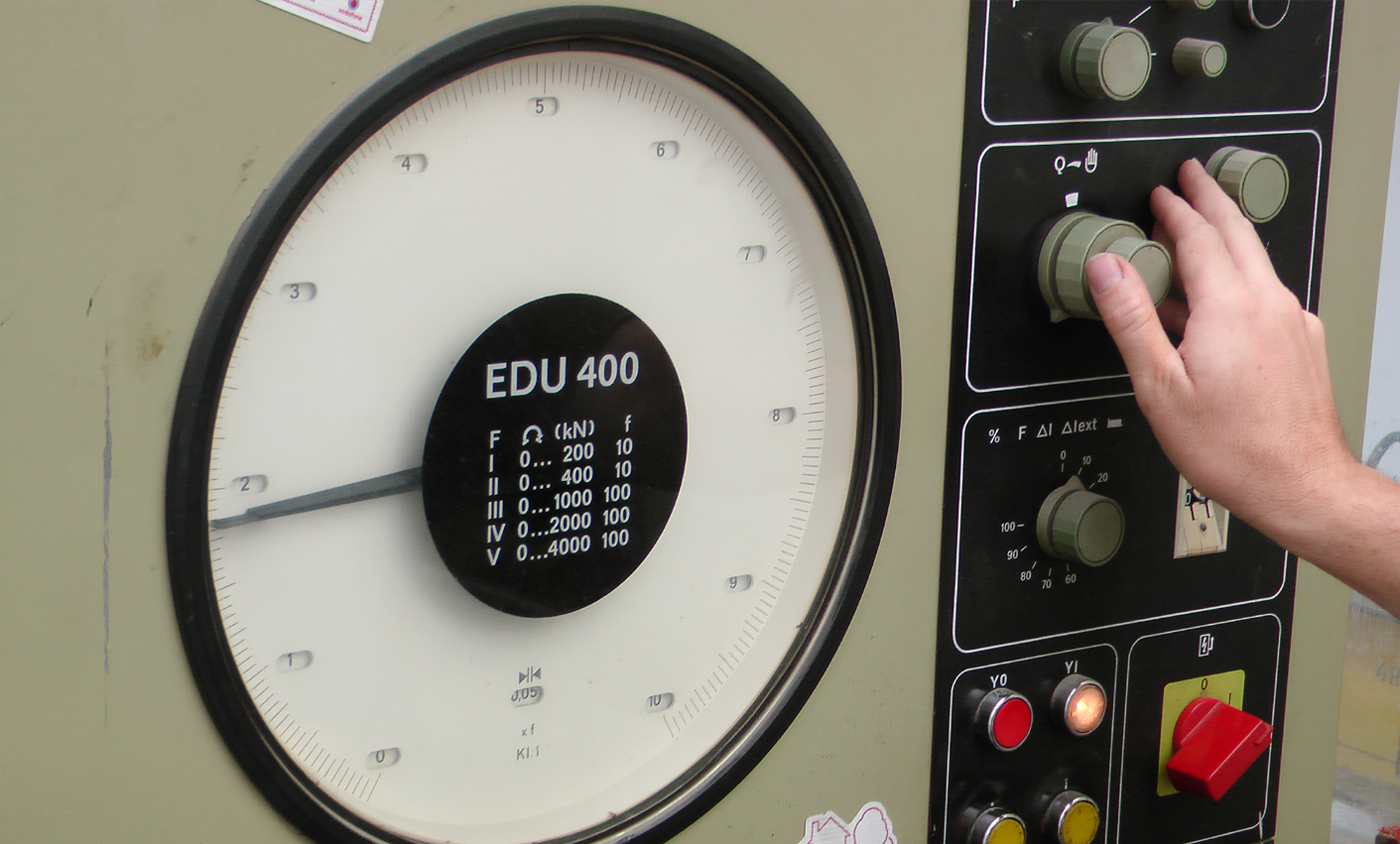

In the last phase of the project, in order to determine the practical workability of the light weight concrete, on July 11, 2014 - at FERROBETON Ltd. plant in Dunaújváros – we realized an experimental test on the supporting end of two structural presstressed light weight concrete supporting structures and their stress distribution.

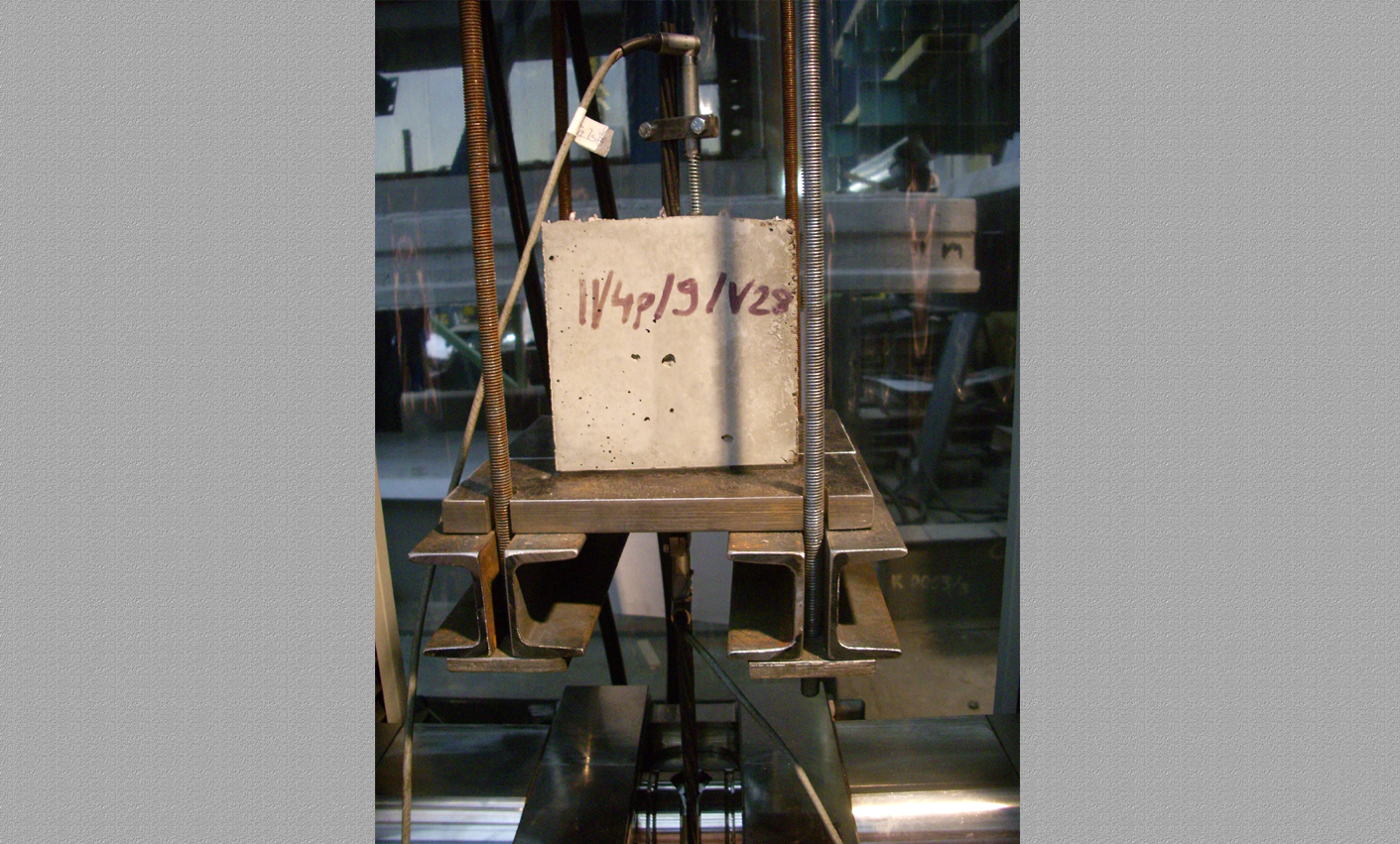

The concrete mixture supporting ends with Liapor aggregate and the test cubes have been prepared for the strength and frost resistance tests with the cooperation of our subconsultants, on July 1, 2014.

The lightweight concrete supporting ends subject to the test were beam ends type FPT- 45. With the purpose of comparison, the same test was carried out on normal concrete beam end as well.

Material grade of the lightweight concrete supporting structure end was LC 50/55.

Material grade of the normalweight concrete supporting structure end was C 50/60 volt.

The supporting ends have been produced with a maximum strand number of the FTP beams and we have tested them at their age of 10 days in the laboratories in Dunaújváros.

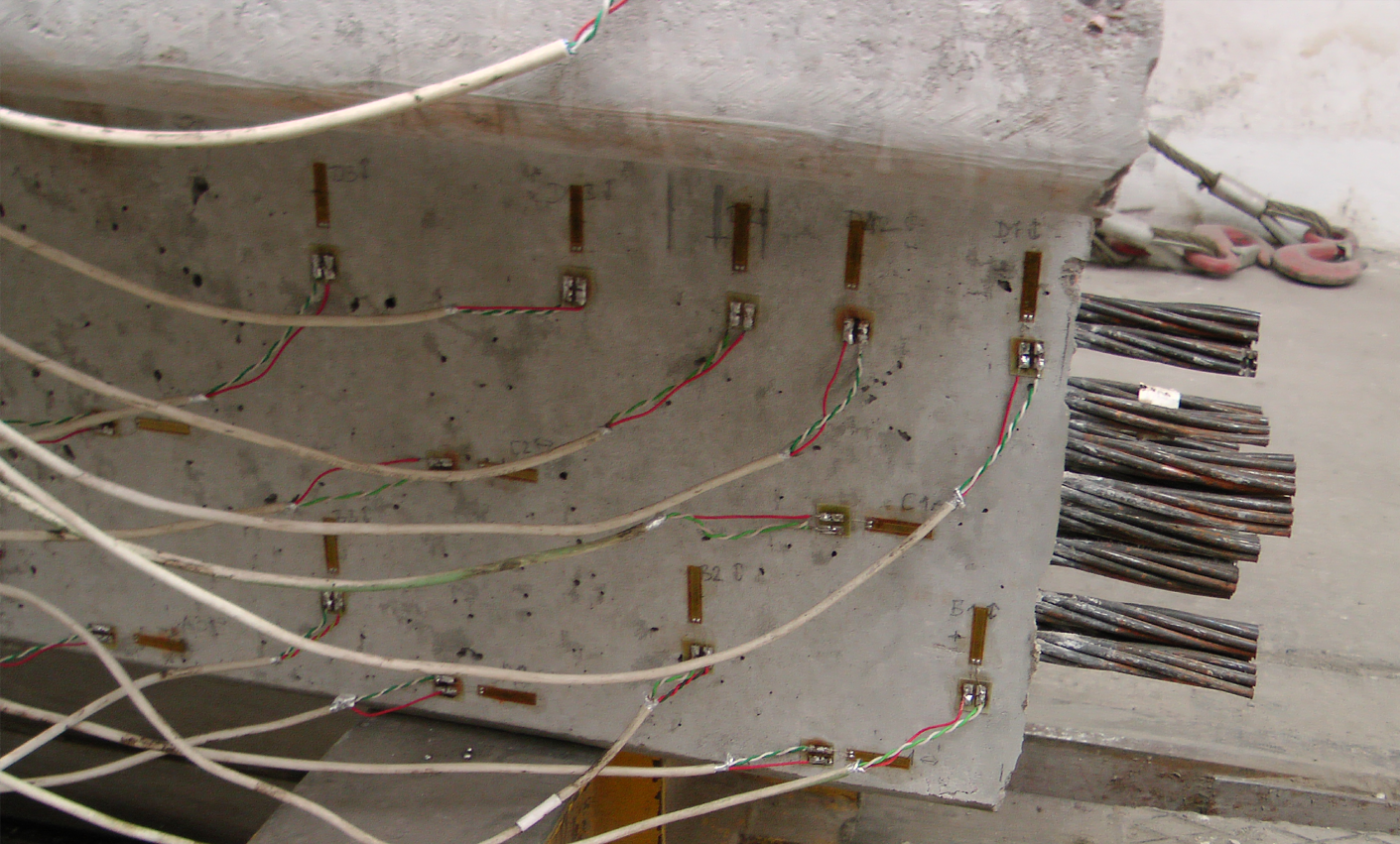

For the analysis of the stress distribution of the supporting ends we glued strain gauges on the concrete surfaces, with the assistance of the experts of the Budapest Technical University Faculty of Civil Enginiing, Department of Structural Engineering.

The stress distribution of the supporting ends has been evaluated on the basis of this test, the processing of which has been carried out by means of the strain gauges data recorded in computer.

The analysis of the vapour treatment action and comparison on the test cubes, furthermore the subsequent analyses of strength and frost resistance were carried out by the experts of the Budapest Technical University Faculty of Civil Engineering, Departmen of Construction Materials and Engineering Geology.

Based on the tests and analyses, numerous statements can be made and many conclusions can be drawn at the present phase of the development work.

Taking into account the complementary materials as well, out of the total of 24 mixes the one showing the best characteristics was the mix prepared with 45% of Lipor 9 type expanded clay aggregate.

As for watertightness, frost resistance and chloride migration further analyses shall be carried out on test specimens, entirely similar to the conditions at production.

Using the results of the above analyses UVATERV Ltd carried out check calculations for a bridge structure of a typical carriageway width of 9,0 m, where the 140 cm high prefab prestressed lightweight concrete bridge beams co-act with the in-situ normalweight rc slab.

In the course of this process we have analyzed the stresses and strains of the bridge beams and of the final bridge structure, considering the data figuring in the “Design Guidelines” submitted to the MAUT system within the frame of this project.

Detailed calculations have been made for the following types of bridge structure:

bridge structure with a span of 26,0 m, made of 5 pieces “IKM140” type bridge beams with a spacing of 2,2 m, co-acting with the in-situ rc slab

bridge structure with a span of 41,0 m, made of 11 pieces of “IKM140” type bridge beams with a spacing of 0,9 m, co-acting with the in-situ rc slab

Regarding the use of light concrete in the practice and its workability it is worthwhile carrying out further researches, since it is a worldwide trend at bridge construction (e.g. in Virginia and Georgia in the US) to apply prefab light concrete beams and even light concrete bridge deck, due to its characteristics of minor dead weight and consequently lower costs of transportation and foundation.

At the last work phase we submitted our copyright on design developed during our R&D work, with the title “Measuring arrangement for the analysis of prestressed lightweight concrete beam ends”.

Based on the outcome of the present R&D project we can state that after having clarified further related details, the results of the present R&D work will offer the possibility of realizing numerous prefabricated products in the future.