| Company Portrait | Quality System | Organigram |

| Board of Directors | Memberships |

Contact |

| Management | History |

Maps |

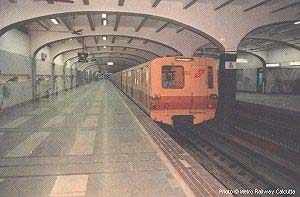

Design of metro lines and tunnels

Location:

Principal:Hindustan Construction Co. Bombay Metropolitan Transport Project (West Bengal) Hungarian co-partners: NIKEX (Foreign Trade Company) KÉV-METRÓ (Construction) BVM (Manufacture of concrete units) UVATERV Ltd. (Design)

Year:1982

Revenue:

Total route length 22.3 km

Stations 21 (15 under ground, 1 on surface and 5 elevated)

Gauge 1676 mm (5 ft 6 in), Indian Broad Gauge

Rolling Stock Trains consist of 8 coaches

Voltage 750 V DC. (third rail current collection)

Headway 7 minutes in peak hours and 10–15 minutes at other times

Automatic Fare Collection(AFC) system with magnetically coded tickets and Passenger Control(PC) system

Description of the design works done by UVATERV:

Features:

Lengths of tunnels:

Section IV/B after the Station Shyam Bazar 2 x 750 m

Section III/B before the Station Belgachia 2 x 350 m

Depths of tunnel: 12-16 m

Outer diameter of the tunnels: 5.50 m

Thickness of lining: 20 cm

Type of lining: one-pass precast segmental lining consists of independent semi-rigid rings each of 7 glued reinforced concrete blocks

Design of tunnel lining, and caissons

Design of tunneling technology and shields

Participation in the training of the local staff in the construction technology

Participation in the manufacture of the reinforced concrete (r/c) segments on site

Supervision of construction

The tunnel, which was driven using hand shields in two directions starting out from diaphragm shafts (launch chambers), is located in young sedimentary layers of the river delta.

Along approximately 90 % of the tunnel length, the originally hinged r/c lining rings were given some stiffness with joints glued with epoxy resin in order to cope with the local conditions presented by the soft clayey soil and fine sand, liable to flow. The tunnels were driven under the protection of compressed air beneath multiple floor residential buildings,

sewers and a railway station.

The r/c tunnel lining system used in Budapest (awarded an EURO PREFAB golden medal in 1979) had been adapted to the soil conditions and engineering capabilities encountered in India. The absolutely unskilled manpower was trained step by step in the know-how of tunnel construction. Periodical presence of the designing staff members on the site was helpful in getting over the difficulties arising during carrying out the works.

Hungarian co-partners of UVATERV:

NIKEX (Foreign Trade Company)

KÉV-METRÓ (Construction)

BVM (Manufacture of the reinforced concrete segments on site)

Time of design: 1978 and 1982

Time of implementation: 1979-1986